Reducing vehicle rollaway risk on

active worksites

Standardized wheel restraint solutions designed to support safe parking procedures across fleets, crews, and equipment types.

The Risk

Vehicle and equipment rollaway incidents continue to occur across construction, industrial, and resource-based worksites.

Inconsistent wheel restraint practices, lost or mismatched chocks, and improvised soloutions increase exposure to uncontrolled movement during parking, maintenance, and loading activities.

ChockMate was developed to address this gap by providing a consistent, repeatable wheel restraint solution that can be applied across a wide range of vehicles and trailers.

The Challenge

On many worksites, wheel restraint practices vary by crew, equipment type, and individual judgement. Loose chocks go missing, incompatible chocks are substituted, and procedures rely heavily on consistency that is difficult to enforce in the field.

In many cases, wheel chocks are treated as loose accessories rather than part of a defined system. Single chocks are stored wherever space allows — buried under other equipment, shifting around in truck boxes, or separated from the vehicles they are intended to secure. This makes correct use less convenient and harder to standardize across crews.

These gaps create variability — and variability increases risk.

A Systemized Approach to Wheel Restraint

On worksites where conditions, equipment, and crews vary, risk is reduced by introducing controls that are consistent, repeatable, and easy to apply correctly.

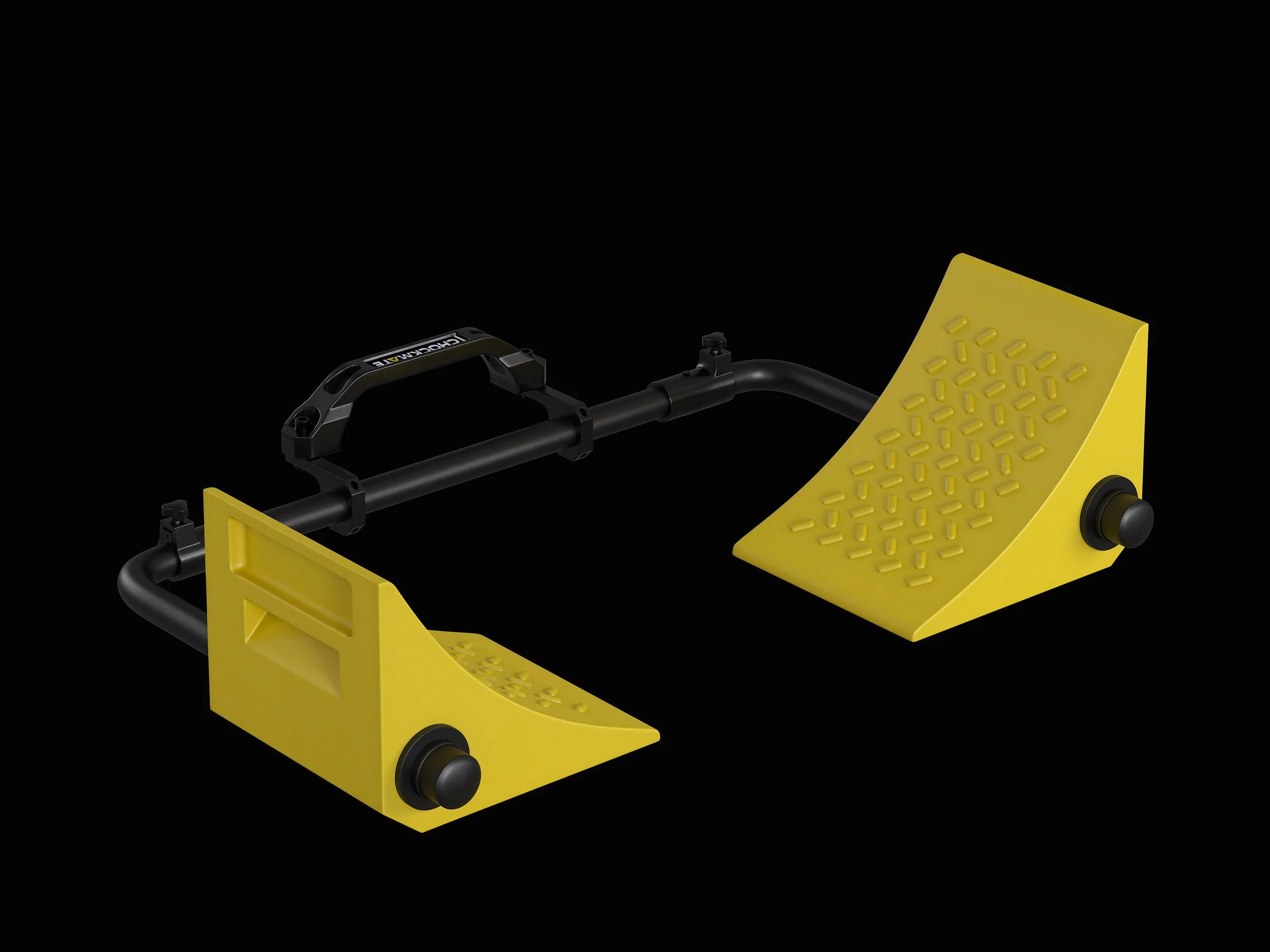

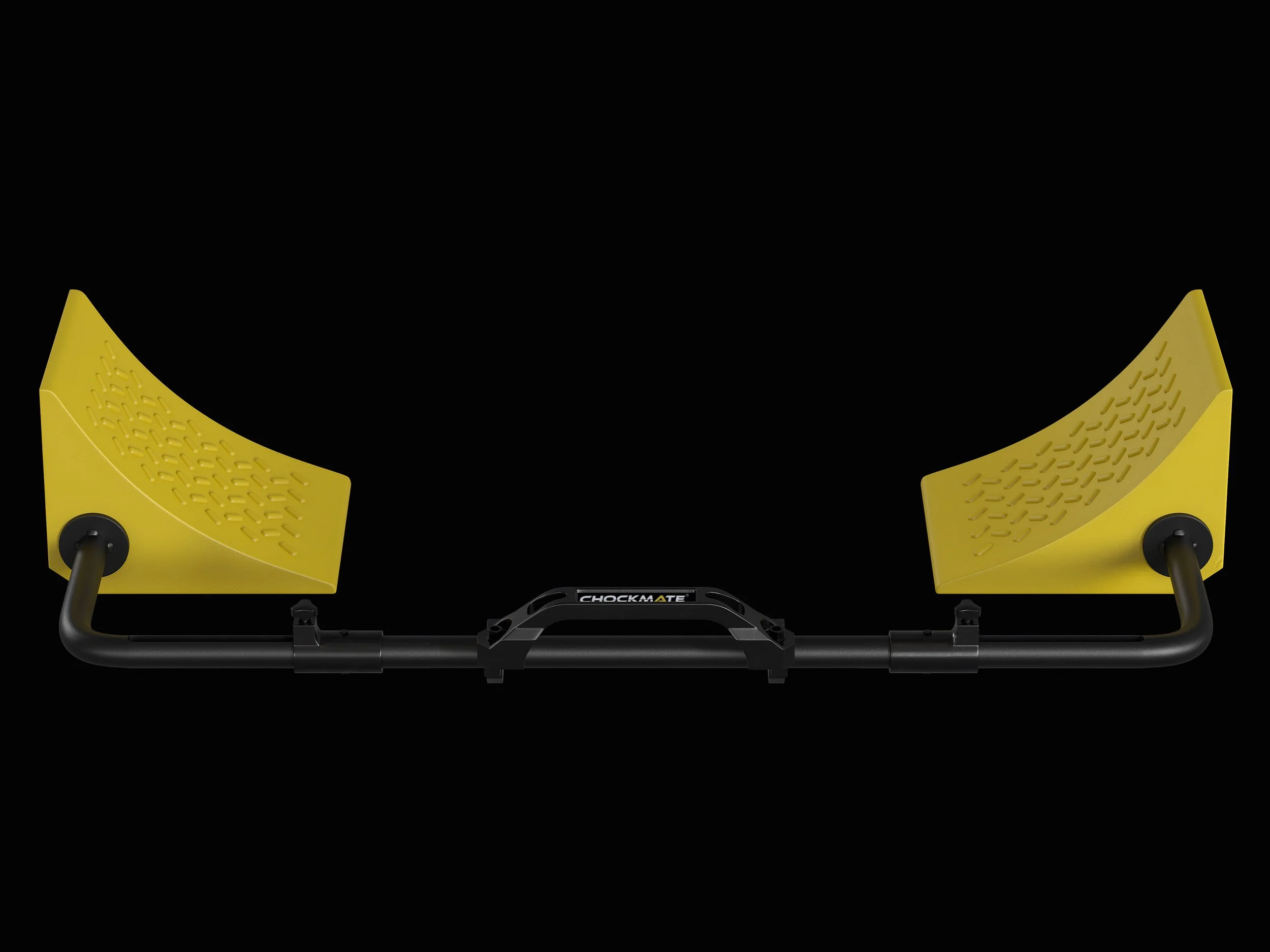

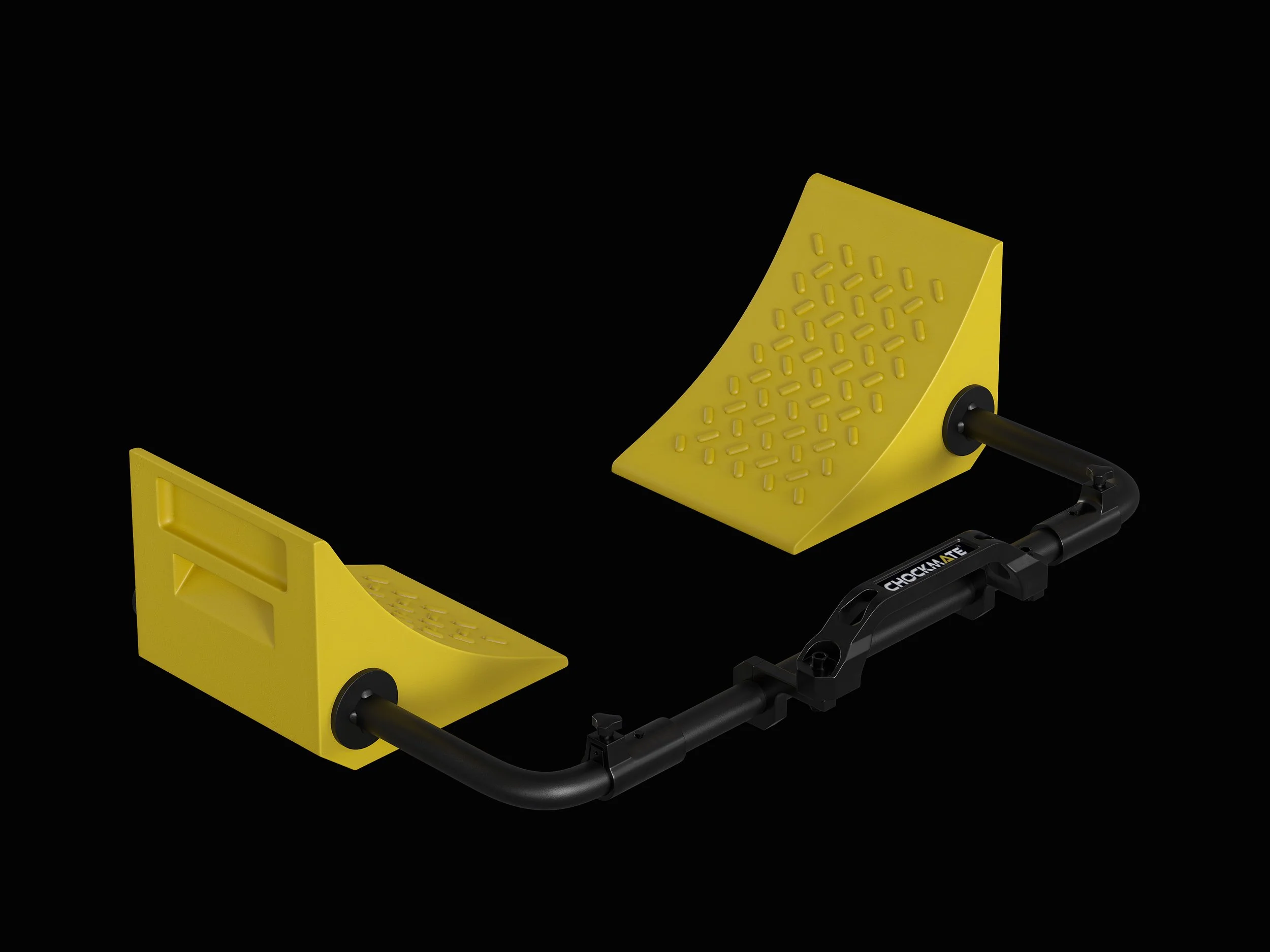

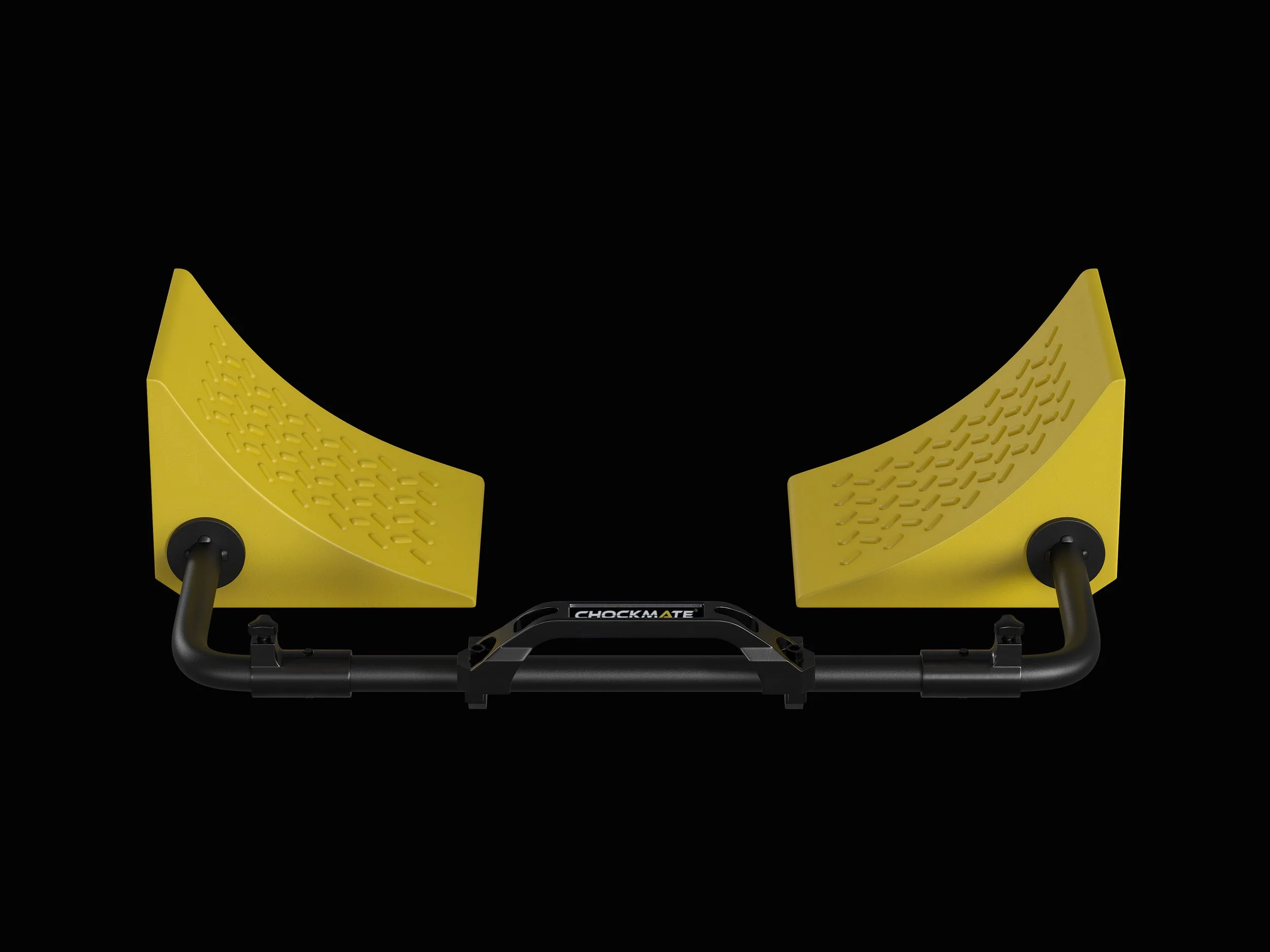

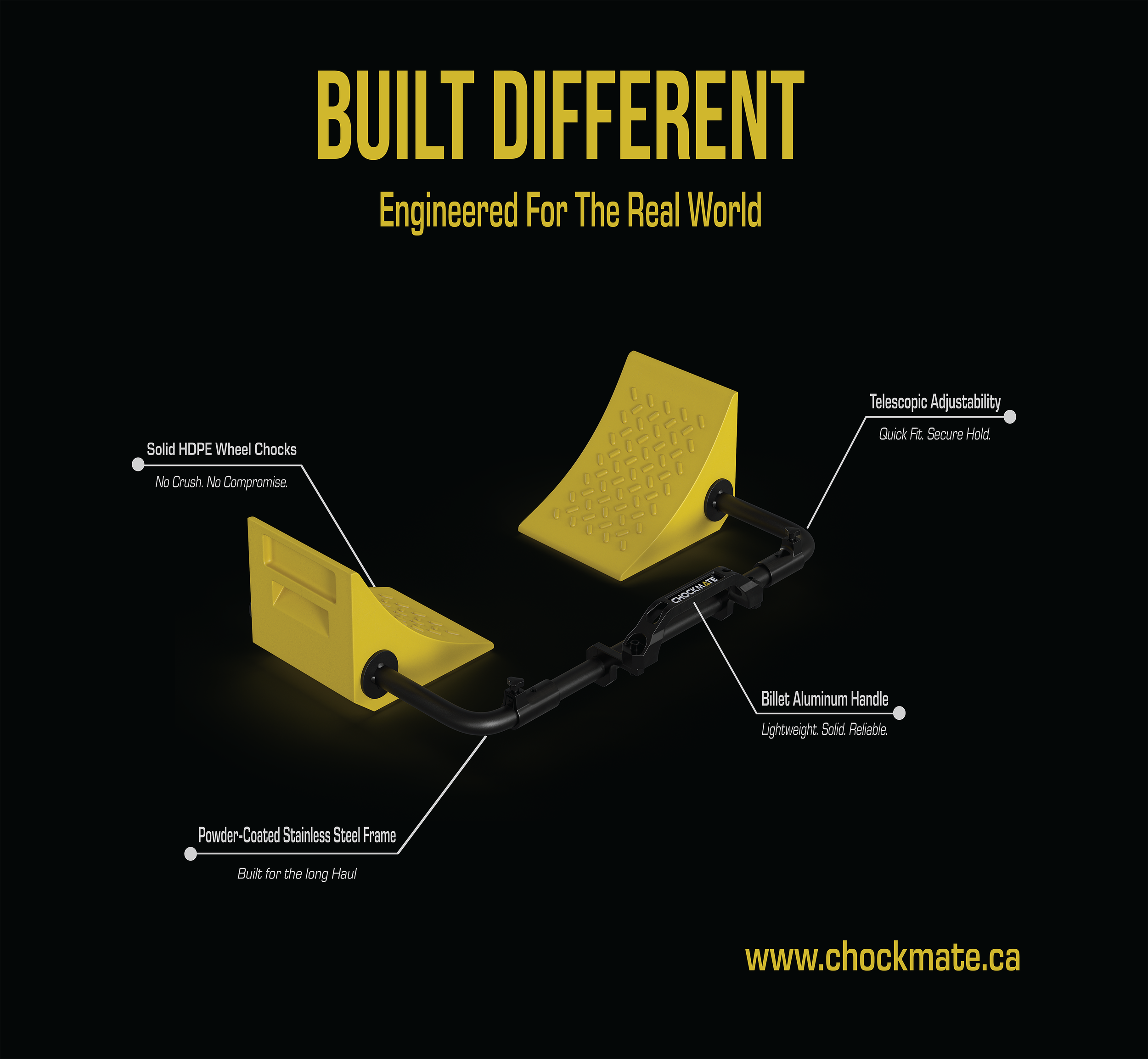

ChockMate was developed as a wheel restraint system, not a standalone chock. By mechanically restraining the wheel on both the forward and rearward faces of the tire, it helps limit inadvertent movement in either direction and supports a more standardized approach to wheel restraint across vehicles and crews.

Rather than relying on multiple loose components, ChockMate functions as a single, integrated solution that is easier to store, easier to access, and easier to deploy consistently in the field.

Compliance & Safety

Supports safe vehicle securing practices

Helps reinforce jobsite compliance expectations

Designed to support established parking and securing procedures

Encourages consistent wheel restraint application across work crews

consistency & ease of use

Supports ergonomic access to wheel restraint equipment

Reduces reliance on single, loose, or improvised chocking methods

helps standardize vehicle-securing procedures in thee field

ChockMate Mounting Clips

Designed for ergonomic ease and organized storage

*Mounting clips sold separately

ChockMate mounting clips are designed to provide ergonomic ease, allowing your ChockMate system to be stored where it’s easy to reach, easy to deploy, and easy to put away.

Mounted inside a truck box, service body, or trailer compartment, the clips keep ChockMate secure, visable and ready for use - eliminating loose equipment, unnecessary bending, and wasted time searching for choks.

By supporting proper placement and consistent storage, mounting clips help reinforce safe work practices while improving efficiency on site.

Designed as a system to support safer, more consistent vehicle securing in real jobsite conditions

FAQ’s

Q: What specific risk does ChockMate address?

A:

ChockMate is designed to help reduce exposure to vehicle rollaway risk during parking, particularly in environments where terrain, surface conditions, or human factors may increase risk.

Q: How does ChockMate address human factors?

A:

The system is designed to be visible, accessible, and easy to use, helping reduce reliance on memory or individual judgment and supporting consistent application across users.

Q: How does this differ from traditional wheel chocks?

A:

Unlike loose chocks that can be misplaced or inconsistently applied, ChockMate is designed as a contained system with designated storage and repeatable placement.

Q: Is ChockMate certified?

A:

There are no formal certification requirements for vehicle securing devices.

ChockMate has been evaluated through field use and internal testing, and is designed to align with commonly recognized life-saving rules related to vehicle securing and rollaway prevention.

Q: Does ChockMate replace existing parking or vehicle securing procedures?

A:

No. ChockMate is designed to support and reinforce existing procedures, not replace them.

It functions as a physical control that helps reduce variability in how vehicles are secured.

Q: Is ChockMate intended to be used alone or as part of a system?

A:

ChockMate is intended to be used as part of a system-based approach to vehicle securing, in conjunction with site-specific procedures, training, and supervision.

Q: What types of vehicles is ChockMate intended for?

A:

ChockMate is designed for light vehicles such as pickup trucks, service vehicles, and similar equipment commonly used on industrial and construction worksites. Each chock has a load rating of 5 ton.

Q: How is ChockMate typically implemented on site?

A:

ChockMate is typically mounted in a designated location within the vehicle, deployed during parking as required by site procedures, and returned to storage after use.

Q: Does implementation require modifications to the vehicle?

A:

No permanent vehicle modifications are required.

Mounting is designed to be straightforward and compatible with common truck boxes and service bodies.

Q: How much training is required?

A:

Training requirements are minimal and typically incorporated into existing vehicle or site-specific orientation and procedures. User manuals come with each unit, and a copy is also available on our website.

Q: Is ChockMate suitable for large-scale deployment?

A:

The system is designed to support consistent use across multiple vehicles, crews, and sites, making it suitable for both small-scale and broader deployment.

Q: How does ChockMate support consistency across crews and shifts?

A:

Designated storage, repeatable deployment, and clear visual confirmation help reduce variability in how vehicle securing is applied.

Q: Does ChockMate require ongoing maintenance or calibration?

A:

No calibration or power source is required.

Routine visual inspection as part of normal equipment checks is typically sufficient. From time to time, the telescopic adjustable arms may need to be lubricated.

Q: Is ChockMate intended for all parking scenarios?

A:

No single control is appropriate for every scenario.

Suitability should always be determined through site-specific hazard assessment and procedures.